What is EMC Testing Labs?

Electromagnetic Compatibility (EMC) is a laboratory consisting of special room and test equipment according to the standards.

How many different EMC Test Lab types are there?

The characteristics or scopes of EMC testing laboratories depend on the product to be tested, the product specifications, the laboratory infrastructure and the test equipment used.

– The laboratory infrastructure and test equipment are divided into international (IEC, CISPR, ANSI …) standards according to whether they are:

Pre-Compliance EMC Test Laboratories:

This type of product developers, designers, manufacturers or universities in this type of EMC laboratories for R & D purposes in the EMC tests are carried out to ensure that the product tested before the full compliance of the tested.This type of EMC labs can be installed and operated at a more affordable cost since the standards are not in full compliance.

Full Compliance EMC Laboratories:

Using EMC testing laboratories and test rooms in accordance with international standards, EMC testing laboratories can provide independent and impartial services, and measurement results and test reports are accepted internationally.Such laboratories can be authorized by authorized accreditation bodies (TÜRKAK, UKAS, DAkkS …).

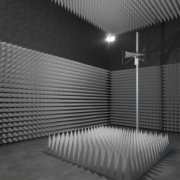

Anechoic Chamber for Radiated Emission and Radiated Immunity tests

According to the product to be tested, there are different EMC Test Laboratories. The EMC test equipment and test laboratory infrastructure used according to the standards to be tested by products determined by IEC, CISPR, ETSI or other international standard organizations vary.

1) Lighting

2) Machines used in Consumer Electronics, IT / Multimedia devices, Light Industry and Industrial Environment

3) Medical Devices

4) Automotive industry vehicles and accessories

5) Railway applications

6) Airplanes

7) Defense Industry

Different types of EMC test laboratories are used depending on the area where the product will be tested and the technical characteristics of the product. The cost of an EMC testing laboratory addressing the lighting industry is different from the EMC testing labs for Automotive or Defense Industry products, as the costs are different.

Robonaut (R2) performed EMI Test by NASA

– EMC testing laboratories can also be classified according to the standards to be tested:

1) IEC / EN 61000-4-2

2) IEC / EN 61000-4-3

3) IEC / EN 6100-4-4

4) IEC / EN 61000-4-5

5) IEC / EN 61000-4-6

6) IEC / EN 61000-4-8

7) IEC / EN 61000-4-11

8) CISPR 22 / EN 55022

9) CISPR 32 / EN 55032

10) CISPR 24 / EN 55024

11) CISPR 35 / EN 55035

12) MIL-STD-461

13) EN 50121-3-2

14) ETSI EN 301 489-1

15) ETSI EN 301 489-17

How to build EMC Laboratories

First of all, technical specifications (maximum voltage, current, power, port numbers, weights and dimensions) and usage areas (home, similar, industry, medical, automotive, defense) should be determined. Since the EMC Test Laboratory to be established will be directly connected to the above properties of the product to be tested technically, the cost of the laboratory will be determined by the above parameters.

After determining the properties and usage areas of the products to be tested, the standards to be applied are determined.

Test laboratory infrastructure (anechoic chamber, screened room, electrical / water system installation, building construction) and EMC test equipment are determined according to the standards to be applied. A list of infrastructure and materials is provided according to the intended use of the EMC test laboratory. At Ege Test Center, we provide turnkey EMC Test Laboratory installation service and device supply services. We are installing EMC test chambers in accordance with the standards of EMC, the designer / manufacturer of Anechoic Chamber. In this way, we offer free laboratory and device usage trainings both theoretical and practical.

DEF STAN 59 411 test chamber

Which Equipment Is Used in the EMC Test Laboratory?

1. Anechoic Chamber (Anechoic Chamber)

2. Screened Room

3. OATS (Open Field Test Site)

4. EMC Antennas

5. EMI Receiver

6. LISN (Line Impedance Stabilization Network)

7. RF cables and connectors

8. Antenna Mast

9. Turntable

10. Camera

11. Absorber

12. RF Power Amplifier

13. ESD Generator (ESD Gun)

14. EFT / Burst Generator

15. Surge Generator

16. Voltage Dips Generator / Simulator

17. Harmonics Analyzer

18. Flicker Analyzer

19. Injection Clamp

20. CDN (Coupling-Decoupling Network)

21. Current probe

22. Voltage probe

23. Isolation transformer

24. Uninterruptible Power Supply (UPS) system

25. Reference Source

26. AM / FM modulator

Com-Power EMC Test Devices

The EMC Test Laboratory infrastructure and EMC test devices mentioned above must be selected according to the standards as a system. EMC tests with appropriate testing software will be facilitated and tested with appropriate parameters.

Ege Test Center EMC Test Laboratory provides services in accordance with international standards to meet the needs of institutions or organizations that want to establish. You can send us your questions and requests from our online application page and you can get more detailed information about EMC Test Laboratories: https://en.egetestcenter.com/contact-us/

In which level should the training of the staff working in the EMC Test Laboratory be?

Administrative and technical personnel in the electromagnetic compatibility testing laboratory should have sufficient knowledge and experience about the tests. The administrative staff should plan and coordinate the interaction of the sample and the product owner with the laboratory to be tested. Technical personnel (test engineer / technician) should have both theoretical and practical knowledge of electromagnetic knowledge. Ege Test Center provides training services to experts or organizations in need of EMC tests with expert test engineers.

Training Services ( Ege Test Center)

Some organizations or organizations receiving EMC testing should have the EMC Test Laboratory to perform these tests themselves. What are the EMC Test Laboratory setup costs? How can small and medium-sized producers have an EMC testing laboratory? We will share our detailed article about costs on this page, continue to follow Ege Test Center.

Our respect…

Ege Test Center

Ege Test Center