Posts

Reducing Product Testing and Certification Costs

Do you regularly need testing and certification services for your products? How to reduce testing and certification costs of your products?

There are some tips to reduce these costs.

Click below link and read more about it:

Full Anechoic Chamber

EMC tests are performed in special test chambers. This EMC chamber is for performing radiated emission and immunity tests. We can measure up to 18GHz.

When you need EMC testing service or radiated immunity testing service click here and send your request online.

Accredited RED, EMC testing

Radio Equipments need testing and certification before putting them in European countries which CE marking directives are mandatory.

Do you want to certify your radio equipments according to Radio Equipment Directive (2014/53/EU) and sell your products to whole Europe?

We are providing EN 17025 accredited testing and certification services according to below ETSI standards.

ETSI EN 300 328

ETSI EN 301 489-1

ETSI EN 301 489-3

ETSI EN 301 489-17

ETSI EN 301 489-52

ETSI EN 301 511

ETSI EN 301 908-1

ETSI EN 301 893

Contact Ege Test Center when you need testing and certification services for your radio equipments: https://en.egetestcenter.com/contact-us/

Radio Equipment Directive (2014/53/EU)

Radio Equipment Directive (2014/53/EU) of European Union is getting popular parallel to technological developments.

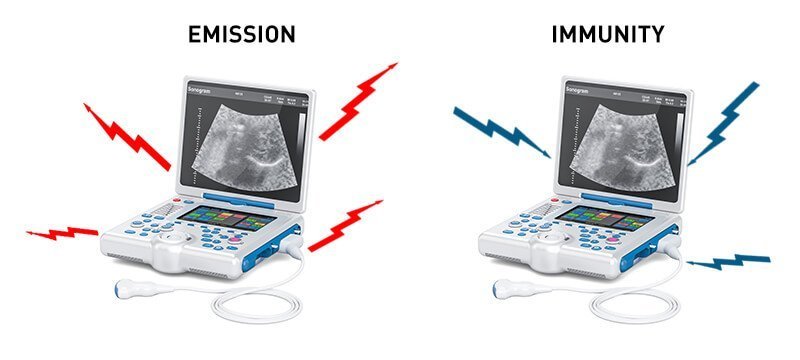

Important of Radiated Emission Testing

Ege Test Center and Radiated Emission Test

Radiated Emission , in other words, by means of Radiated Propagation is only one of the Electromagnetic Compatibility (EMC) tests. According to the product to be tested according to the EMC standard is determined after determining an anechoic chamber (anechoic chamber) or in the open field test area (OATS) is a test must be done. The purpose of the Radiated Emission test is to determine whether the unwanted electromagnetic frequencies of the product are below a certain level. Radiated EmissionIf the measurement results of a product being tested are below the limit values specified in the relevant standard, this test is considered to have passed. If the measurements on the limit are obtained, a change in design or EMC is required on the remaining product. The studies carried out on this kind of product are R & D studies and are very important works for the producer.

What You Need to Know About Radiated Emission Test

The measured frequency range of the Radiated Emission tests usually starts at 30 MHz and can be up to 1GHz, 2GHz or 6GHz depending on the product specification and the applied standard. Measurements are made with the antennas designed for the specified frequencies and the measurement devices called the EMI Receiver. The measuring distance between the product and the antenna is usually 3 meters or 10 meters. It is also possible to change the limits according to the measuring distance. For example, the limit value of 40 dBuV / m at 3 m can be reduced to 30 dBuV / m if the measurement is done at 10 m.

The Radiated Emission test is one of the most basic tests of EMC tests, so it is a test that the product designers should be familiar with. Measures related to EMC testing of a product should start at the design stage of the product and continue during the serial production phase. Even when the product is in the end user, it should be followed.

EMC Test for Medical Devices

The Importance of Medical Devices in Our Lives

Nowadays, the medical devices used in medicine are very important. Ultrasound, magnetic resonance, dentist chair, radiological methods, such as the diseases formed in our body to be seen in the finest detail is possible to see. There are EMC tests that must be applied to medical devices used in medicine, the accuracy and construction of these tests is very important. In the case of improper application of parts, such as standard, test coverage, human health is at great risk when any problem occurs.

The Importance of CE Marking for Medical Devices

The CE marking is of great importance for the medical devices to easily move around Europe. The EMC tests of these types of medical products and the CE Marking carry important factors such as health, safety, environment and consumer protection.

To get CE Mark on Medical Devices

Ege Test Center team of experts is implementing in conjunction with the first of medical devices accredited scope of the EMC Tests and reporting stage in your side apply.medical your device accredited in scope to get the Ege Test Center marketing-at-egetestcenter.com could e-mail address or https://www.egetestcenter.com/apply-online/ You can reach us by filling in the form.

Why Pre-Compliance EMC Testing?

Electromagnetic Compatibility (EMC) testing is one of the essential requirements prior to marketing electrical products. Most of the electrical equipments need EMC testing due to some technical and legal reasons. EMC test standards are varying according to the region or country that the product will be marketed to. Product designers and manufacturers have to be aware of these standards and shall market their products according these regional or international standards. Prior to full compliance EMC testing, pre-compliance EMC testing plays an essential role. By performing some of EMC tests in their own facilities, product designers and manufacturers will ensure that their products fulfill EMC testing standards partially. This will give them a great advantage prior to full compliance EMC testing or certification of the products by third party testing laboratories.

In order to set up a pre-compliance EMC testing laboratory, there are many solutions on the market. These solutions depend on the features of the Equipment Under Test (EUT). By listing the EMC test standards and specific tests according the product features, EMC testing chambers or equipments can be selected. These pre-compliance EMC test equipments will not cost as much as accredited EMC testing laboratories since some deviations can be ignored due to the tests are pre-compliance.

Picture link: https://www.com-power.com/images/products/systemn.jpg

Remark: This post is firstly published on Linkedin by Yusuf Ulas KABUKCU: https://www.linkedin.com/pulse/why-pre-compliance-emc-testing-yusuf-ulas-kabukcu/

Automotive EMC Test: CISPR 25, ISO 11452-2 and Equivalent Standards

Room Testing for EMC Standards and Automotive Components

Automotive standards for electromagnetic compatibility (EMC) are mainly developed by CISPR, ISO and SAE. CISPR and ISO are organizations that develop and maintain international standards of use. SAE develops and maintains standards for use primarily in North America. In the past, the SAE has developed several EMC standards, which were eventually submitted to CISPR and ISO for consideration as an international standard. When SAE standards become international standards, the equivalent SAE standard is withdrawn as a full standard and is reserved for use in documenting differences in international standards.

Each vehicle manufacturer has internal standards that determine the levels and tests that the components used in their vehicle must meet. As with government standards, these documents often refer to CISPR and ISO documents, which differ in scope or test levels. In the past, a US-based vehicle manufacturer has applied SAE documents to corporate standards. Most of today

USA-based vehicle manufacturers worldwide market. For this reason, they refer to CISPR and ISO standards in their internal standards, and this applies to other established and developing manufacturers.

|

Document number. |

Title |

medicine |

Equivalent |

Test setup |

Room Requirement |

|

ISO-11451-1 |

Road vehicles – Vehicle testing methods for electrical distortion from electromagnetic energy with impact spread – Part 1: General principles and terminology |

N / A |

SAE J551 / 1 |

Definitions |

N / A |

|

ISO-11451-2 |

Chapter 2: In-Car Radiation Sources |

ru |

SAE J551-11 (Note 1) |

Immune test in an anechoic chamber |

Car shock absorber covered room |

|

ISO-11451-3 |

Part 3: Built-in transmitter simulation |

ru |

SAE J551-12 (Note 2) |

Vehicle Absorbent Lined Shielded Enclosure (ALSE) required |

Car shock absorber covered room |

|

ISO-11451-4 |

Part 4: Mass Flow Injection (BCI) |

ru |

SAE J551 / 13 (Note 3) |

The test is designed for machines and vehicles that are too large to fit into a standard EMC. |

Open Test Area (OTS) or Vehicle Absorbent covered room |

CISPR 25 and CISPR 12

The CISPR 25 is typically not used for regulatory purposes, but is commonly used by vehicle manufacturers to ensure good performance of vehicle-mounted receivers. If the radio installed in the vehicle, boat or other device does not perform reliably, consumer satisfaction and consequently product sales may be damaged.

Both CISPR 12 and CISPR 25 relate to vehicles operating on internal combustion engines (land-based vehicles), boats working with internal combustion engines (vehicles running on the water surface), and devices (but not necessarily) that work with internal combustion engines. for the transport of people). This latest category includes compressors, chainsaws, garden equipment and so on. It contains. CISPR 12 applies to all of these devices, as this may affect the performance of nearby (external) receivers. However, CISPR 25 should only be considered for products containing built-in receivers. For example, a chain saw with an internal combustion engine (but without built-in receivers) must meet the requirements of CISPR 12, but CISPR 25 does not use any built-in receiver for this saw.

CISPR 12 emitted emission measurements are made at 3-meter or 10-meter test distances. Measurements are normally made in an outdoor test area (OTS) or ALSE in an absorbent coated shield if the ALSE can be correlated with an OTS. Measurements can also be made for boats for water. The correlation of ALSE with an OTS has been a topic of discussion within the group of experts responsible for maintaining CISPR 12 over the past few years. The specification does not currently provide a method for obtaining this correlation. A working group is tasked with developing a method for associating ALSE with OTS; However, this may take more than a few years and we are expecting CISPR 12 then published in newer version.

For test and information

For more detailed information about the tests of EMC, please send an e-mail to marketing-at-egetestcenter.com or fill out the form at https://en.egetestcenter.com/apply-online/ .

EMC Directive in non-EU States, countries & territories

European Union published a guide regarding Electromagnetic Compatibility (EMC) directive: Guide for the EMCD (Directive 2014/30/EU)

As this EMC Directive Guide mentions, the geographical application is described in Chapter 2.8 “geographical application” of the Blue Guide. The EMCD also applies in the EEA-EFTA States (Liechtenstein, Iceland, and Norway) and Turkey. Therefore, when the terms “European Union”, “Union”, “territory” or ‘Member States’ are used in this Guide, they apply to the EEA-EFTA States (Liechtenstein, Iceland, and Norway) and Turkey.

How to get EMC testing services?

You have to contact an EMC testing laboratory expert who is experienced in EMC testing. Ege Test Center experts provide you required information about EMC testing and certification of your product. Do you want to pass EMC tests and affix CE marking on your products? Contact us by visiting our contact page.

Ege Test Center helps designers, manufacturers, engineers, importers, exporters, researchers, universites and all other parties need EMC testing according to EMC Directive. You can ask any question regarding EMC Directive or send your request by using our Online Application form: https://en.egetestcenter.com/apply-online/